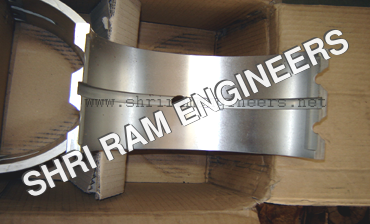

B&W 25 MTBH 40 Engine Part

Price 1000.00 INR/ Unit

B&W 25 MTBH 40 Engine Part Specification

- Operating Temperature

- -20C to +80C

- Flow Rate

- Variable

- Working Pressure

- Standard Marine Grade

- IP Rating

- IP54

- Usage & Applications

- Marine engine spare part, Industrial diesel engine maintenance, Ship propulsion system refurbishment

- Equipment Type

- B&W 25 MTBH 40 Engine Component

- Application Areas

- Marine vessels, Shipyards, Heavy industries

- Capacity

- 300-600 HP (Horsepower)

- Product Type

- Engine Part

- Type

- Diesel Engine Spare Part

- Material

- Forged Steel

- Automatic Grade

- Manual

- Control System

- Mechanical

- Drive Type

- Direct Driven

- Weight (kg)

- 125

- Dimension (L*W*H)

- 1200 x 800 x 350 mm

- Feature

- High durability, Precision engineered, Corrosion resistant, Easy installation

- Size

- Custom fit for 25 MTBH 40

- Surface Finishing

- Smooth, Rust-proof

- Power Source

- Diesel

- Features

- Long service life, Sturdy construction, Precisely machined

- Mounting Type

- Flange Mounted

B&W 25 MTBH 40 Engine Part Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About B&W 25 MTBH 40 Engine Part

ITEM NAME | PART NO. |

|---|---|

| INLET VALVE CAGE | |

| EXHAUST VALVE CAGE | |

| FUEL TAPPET GUIDE | |

| VALVE SPRING | |

| PIPE PUSH ROD | |

| CONNECTING ROD BOLT | |

| ST. VALVE COMP. | |

| INLET VALVE | |

| AUTOMIZER WITHOUT NOZZLE | |

| GUDGEON PIN | |

| TAPPET WITH ROLLER BIG | |

| TAPPET WITH ROLLER SMALL | |

| TAPPET ROLLER | |

| TAPPET ROLLER PIN | |

| EXHAUST VALVE | |

| VALVE CUP | |

| OIL PUMP GEAR | |

| PUSH ROD | |

| CYLINDER HEAD WITH LINER | |

| ROCKER LEVER | |

| ROCKER SHAFT | |

| MAIN BEARING | |

| PISTON | |

| AUTOMIZER COMP | |

| VALVE CAM | |

| FUEL CAM | |

| SAFTEY VALVE WITH INJECTOR COCK | |

| GUDGEON PIN LOCK | |

| ROCKER BUSH | |

| PUSH ROD | |

| GUDGEON PIN BUSH | |

| FUEL PIPE | |

| FUEL PUMP | |

| FUEL CAM | |

| SAFETY VALVE |

Precision Engineering for Robust Performance

Every B&W 25 MTBH 40 Engine Part is manufactured using high-grade forged steel and advanced machining processes, resulting in exceptional precision and sturdiness. Its corrosion-resistant finish and adherence to IP54 standards guarantee longevity and reliability, even in demanding marine environments.

Versatile Application Across Industries

This engine spare part is specifically engineered for direct-drive systems in marine vessels, shipyards, and heavy industries. Its compatibility with 25 MTBH 40 series engines ensures seamless integration for maintenance, ship propulsion refurbishment, and industrial diesel engine applications.

FAQs of B&W 25 MTBH 40 Engine Part:

Q: How do I determine if the B&W 25 MTBH 40 Engine Part is compatible with my equipment?

A: This part is custom-fit for B&W 25 MTBH 40 series engines. Check your engine model specifications or part number to confirm compatibility before purchase.Q: What is the standard process for ordering OEM/ODM variants of this engine part?

A: OEM/ODM variations are available upon request. Contact your authorized distributor or supplier to discuss specifications, place your order, and confirm lead times.Q: When should this spare part be replaced during engine maintenance?

A: Replacement should follow the engine manufacturers maintenance schedule, ensuring optimal engine performance and longevity.Q: Where is this engine part applicable beyond marine vessels?

A: Besides ship propulsion systems, this component is widely utilized in shipyards, heavy industrial operations, and diesel engine maintenance environments.Q: How does proper lubrication impact the operation of this part?

A: Lubrication is mandatory during operation, minimizing friction and wear, which ensures long service life and maintains efficiency of the engine system.Q: What are the benefits of choosing this forged steel part over alternatives?

A: Its forged steel construction provides superior durability, precision engineering, corrosion resistance, and easy installation, resulting in lower maintenance costs and longer service intervals.Q: What packaging and delivery timeline should I expect when ordering this part?

A: Each part is shipped in export-standard wooden crates, with lead times typically ranging from 7 to 15 working days, depending on stock availability and order specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in B & W Marine Engine Parts Category

Marine Generator Spare Parts

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Manual

Control System : Compatible with marine generator control panels

Size : Varies (custom and standard sizes available)

Drive Type : Other, Mechanical/Electrical

B&W 26 MTBH-MTBF 40

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Automatic

Control System : Electronic

Size : DN80

Drive Type : Other, Electric Motor Drive

B&W 320 MTBH 30

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units, ,

Automatic Grade : Automatic

Control System : PLC Based Automatic Control Panel

Size : Standard (Contact Manufacturer for Details)

Drive Type : Electric

B&w engine spare parts

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Other, Manual and semiautomatic available

Control System : Mechanical/Electromechanical

Size : Standard & custom sizes available

Drive Type : Other, Direct drive

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry