B&W 26 MTBH-MTBF 40

Price 1000.00 INR/ Unit

B&W 26 MTBH-MTBF 40 Specification

- Operating Temperature

- 5C - 55C

- Working Pressure

- 10 Bar

- IP Rating

- IP55

- Flow Rate

- 40 m3/hr

- Application Areas

- Water Treatment, Industrial Processing, Cooling Water Systems, Pre-filtration

- Equipment Type

- Mechanical Self-Cleaning Filter

- Capacity

- 40 m3/hr

- Usage & Applications

- Industrial Applications, High Pressure Filtration, Mining, Oil & Gas, Power Plants

- Product Type

- Backwash Filter

- Type

- Automatic Self-Cleaning Filter

- Material

- Mild Steel

- Automatic Grade

- Automatic

- Control System

- Electronic

- Drive Type

- Electric Motor Drive

- Weight (kg)

- Approx 500 kg

- Dimension (L*W*H)

- 2200*1050*1750 mm

- Feature

- High Reliability, Robust Construction, Easy Maintenance

- Size

- DN80

- Surface Finishing

- Epoxy Coated

- Power Source

- Electric

- Voltage

- 380V

- Mounting Type

- Floor Mounted

- Features

- Continuous Filtration, Automatic Cleaning Cycle, High Dirt Holding Capacity

B&W 26 MTBH-MTBF 40 Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About B&W 26 MTBH-MTBF 40

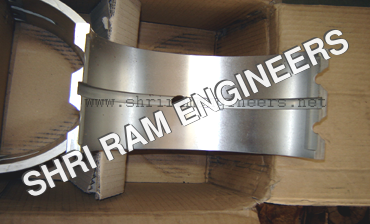

ITEM NAME | PART NO. |

|---|---|

| COMPRESSION RING | A 106A, AER.2 |

| OIL SCRAPPER RING | A 106A, POS.3 |

| OIL DISTRIBUTION RING | A-106A, POS.3 |

| INLET VALVE | C101A, POS.6 |

| OUTLET VALVE | C102A, POS.6 |

| CONROD BEARING NOMINAL | A106A, POS.16, 17 |

| ROCKER IN ASSEMBLY | B103A, POS.7, 20 |

| VALVE GUIDE | A105A, POS.15 |

| COVER WATER BOX | A 105A, POS.3 |

| ROLLER GUIDE | B 103A, POS.37 |

| PISTON | A 106A, POS.1 |

| ROCKER ARM BEAM | B 103A, POS.1 |

| ROCKER ARM INLET IN ASSEMBLY | B 103A, POS.7 |

| ROCKER SHAFT | B103A, POS.13 |

| ROCKER SHAFT | B 103A, POS.14 |

| BUSH ROCKER ARM BEAM | B 103A, POS.2 |

| GUIDE WHEEL | B 103A, POS.48 |

| GUIDE WHEEL | B 103A, POS.11 |

| INJECTOR IN ASSEMBLY | C 103A, POS.20 |

| STARTING VALVE | C 106A, POS.12 |

| PLUNGER AND BARREL 18MM LEFT | E 101A, POS.15, 30 |

| FUEL PUMP IN ASSEMBLY | E 101A, POS.31 |

| PRESSURE VALVES IN ASSEMBLY | E 101A, POS.13 |

| NUT | E 101A, POS.6 |

| NOZZLE | C 103A, POS.8 |

| SPINDEL | C 103A, POS.9 |

| COTTER | C 103A, POS.10 |

| MULTIPIECE CON RING | C 103A, POS.2 |

| BUSH | B 104A, POS.15 |

| ROLLER | B 104A, POS.16 |

| ROLLER PIN | B 104A, POS.13 |

| MAIN BEARING COMPLETE | A-102-A, POS.5,11 |

| THRUST BEARING COMPLETE | A-102-A, POS.57,50 |

| CYLINDER LINER | A-105-A, POS.21 |

| BIG END BEARING COMPLETE | A-106-A, POS.16,17 |

| PISTON COMPRESSION RING | A-106-A, POS.2 |

| PISTON OIL SCRAPER RING | A-106-A, POS.3 |

| FUEL INJECTION VALVE COMPLETE | C-103-A, POS.20 |

| PLUNGER PAIR FOR FUEL INJECTION PUMP COMPLETE | E-101-A, POS.10 |

| SPRING FOR FUEL INJECTION PUMP | E-101-A, POS.10 |

| INLET VALVE | C-101-A, POS.6 |

| EXHAUST VALVE SPINDLE | C-102-A, POS.6 |

| PISTON | A-106-A, POS.1 |

| CYLINDER HEAD (BORE) | A-105-A, POS.1 |

| GUIDE THRUST BEARING | A-102-A, POS.57,50 |

| CYLINDER LINER | A-105-A, POS.21 |

| O-RING FOR CYLINDER LINER | A-105-A, POS.20 |

| PISTON COMRESSION RING | A-106-A, POS.2 |

| PISTON OIL SCRAPER RING | A-106-A, POS.3 |

| INLET VALVE SPINDLE | C-101-A, POS.6 |

| EXHAUST VALVE SPINDLE | C-102-A, POS.6 |

| UPPER MAIN BEARING SHELL | A-102-A, 5 |

| UPPER LEAD BEARING SHELL | A-102-A, 6 |

| CYLINDER HEAD | A-105-A, 1 |

| CYLINDER LINER | A-105-A, 21 |

| RUBBER RING | A-105-A, 20 |

| PISTON | A-106-A, 1 |

| PISTON RING | A-106-A, 2 |

| OIL SCRAPER RING | A-106-A, 3 |

| LOWER CONNECTING ROD SHELL | A-106-A, 16 |

| CONNECTING ROD UPPER END BUSH | A-106-A, 7 |

| SUCTION VALVE | C-101-A, 6 |

| EXHAUST VALVE | C-102-A, 6 |

| ROCKER EXHAUST VALVE | 14, 23, B103A, POS. 8, |

| BALANCE OF ROCKER | POS. 2-5, 15, 16, A103 ANR.1:NR.19 |

| PUSHER | B103A, POS.27 |

| PUSHER | B103A, POS.58 |

| GUIDE ROLLER | B103A, POS.37 |

| GUIDE ROLLER | B103A, POS.48 |

| ROCKER INLET VALVE | B103A, POS.7 |

| GUIDE ROLLER | B104A, POS.11 |

| SPRING | POS.4-6 |

| PISTON PIN | POS.5 |

| FUEL INJECTION PUMP | E101A, POS.31 |

| INJECTOR COMPLETE | C-103-A, POS.20 |

| SPINDLE GUIDE | C-103-A, POS.11 |

| FUEL PUMP | E-101-A, POS.31 |

| PLUNGER | E-101-A, POS.30 |

Exceptional Filtration Efficiency

The 26 MTBH-MTBF 40 filter delivers consistent and efficient filtration with a standard 100-micron screen, ensuring optimal performance in high-pressure environments. Its flexible filtration range (50500 microns) allows customization according to specific industry requirements, enhancing water quality and process reliability across power plants, mining, and oil & gas sectors.

Automatic Self-Cleaning Technology

Featuring a motorized suction nozzle, the filter conducts automatic cleaning cycles, reducing manual intervention and ensuring uninterrupted operation. The electronic control system manages the cleaning process seamlessly, making maintenance both straightforward and cost-effective. This translates into extended filter life and minimal downtime.

Rugged and Reliable Construction

Built with mild steel and finished with industry-grade epoxy coating, this filter is designed for durability and broad compatibility in industrial environments. With an IP55 rating and motor power of 0.75 kW, it withstands challenging conditions. Its compact dimensions and flanged end connections facilitate easy installation and long-term operation in diverse applications.

FAQs of B&W 26 MTBH-MTBF 40:

Q: How does the automatic self-cleaning mechanism function in the B&W 26 MTBH-MTBF 40?

A: This filter uses a motorized suction nozzle driven by an electric motor to remove accumulated debris from the filter element automatically. The process is managed through an electronic control unit, initiating cleaning cycles as needed, thus maintaining filtration efficiency without manual intervention.Q: What types of applications is the 26 MTBH-MTBF 40 suitable for?

A: The filter is designed for a broad range of industrial uses, including water treatment plants, cooling water systems, mining operations, power generation, oil & gas facilities, and pre-filtration for various processes, making it a versatile solution for high-pressure and high-demand environments.Q: When should the filtration fineness option be changed from the standard 100 microns?

A: The filtration fineness setting should be adjusted based on the solids present in your feedwater and the quality requirements of the downstream processes. For applications demanding finer filtration or when handling finer particulates, you can select screens ranging from 50 to 500 microns.Q: Where is the 26 MTBH-MTBF 40 typically installed within industrial infrastructure?

A: This self-cleaning filter is floor-mounted and generally positioned upstream in water treatment lines, cooling circuits, or processing flows, where continuous filtration and high flow rates are essential to protect critical equipment and processes.Q: What are the main benefits of using this automatic self-cleaning filter in an industrial setup?

A: Benefits include continuous filtration with minimal manual supervision, reduced operational downtime, easy maintenance, robust construction for durability, and adaptability to various industrial liquids and water sources. Its high dirt-holding capacity and automated operation optimize both productivity and cost efficiency.Q: How is the maintenance process managed for this equipment?

A: Routine maintenance is straightforward due to the automatic cleaning system. Operators primarily need to monitor the filter for any operational alerts via the electronic control panel and conduct periodic inspections of mechanical parts and seals to ensure system integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in B & W Marine Engine Parts Category

Bergen KRG 6 Diesel Engine Spare Parts

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Application Areas : Marine vessels, industrial diesel power plants, large generator systems.

Weight (kg) : Varies by individual spare part component.

Automatic Grade : Other, Manual and semiautomatic options available (depending on component).

Feature : Other, Precision engineered, high durability, superior fit and performance.

Marine Generator Spare Parts

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Application Areas : Ships, offshore platforms, marine vessels

Weight (kg) : Varies by part, typically 0.5 kg 25 kg

Automatic Grade : Manual

Feature : Other, High durability, corrosionresistant, precision engineering

B&W 25 MTBH 40 Engine Part

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Application Areas : Marine vessels, Shipyards, Heavy industries

Weight (kg) : 125

Automatic Grade : Manual

Feature : Other, High durability, Precision engineered, Corrosion resistant, Easy installation

B&W 8T 23 LH

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Application Areas : Shipyards, Marine Engineering, Heavy Equipment Lifting

Weight (kg) : 23 kg

Automatic Grade : Manual

Feature : Other, High durability, Rust resistant, Robust design

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry