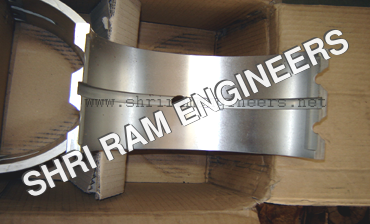

B&W 8T 23 LH

Price 1000.00 INR/ Unit

B&W 8T 23 LH Specification

- Capacity

- 8 Ton

- Application Areas

- Shipyards, Marine Engineering, Heavy Equipment Lifting

- Equipment Type

- Engine Lifting Hook

- IP Rating

- IP54

- Operating Temperature

- -10C to 60C

- Usage & Applications

- Marine engine lifting balancing

- Type

- Lifting Hook

- Material

- Alloy Steel

- Automatic Grade

- Manual

- Control System

- Hand Operated

- Drive Type

- Mechanical

- Weight (kg)

- 23 kg

- Dimension (L*W*H)

- 315mm x 205mm x 65mm

- Feature

- High durability, Rust resistant, Robust design

- Size

- Standard

- Power Source

- Manual

- Surface Finishing

- Galvanized

- Features

- Corrosion protection, Heavy-duty construction

- Mounting Type

- Custom mount

B&W 8T 23 LH Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About B&W 8T 23 LH

Exceptional Durability & Corrosion Protection

Built with premium alloy steel, the B&W 8T 23 LH lifting hook offers high durability and excellent rust resistance. Its galvanized finish shields it from harsh marine conditions, ensuring a long service life for heavy-duty applications. These features make it a reliable choice for industries requiring consistent lifting performance in corrosive environments.

Engineered for Marine and Heavy Equipment Lifting

Optimized for use in shipyards and marine engineering, the 8T 23 LH accommodates lifting and balancing of heavy engines with ease. Its mechanical drive type and manual operation provide safety and precise control, while a custom mounting option supports varied application needs. With an 8-ton capacity, it meets the demands of large-scale equipment handling.

Trusted by Professionals Across India

Supplied by a network of dealers, exporters, and fabricators, the B&W 8T 23 LH is a product of choice for marine and heavy equipment sectors in India. Its adherence to industrial standards, coupled with robust design and IP54 protection, has established it as a reliable solution for professionals seeking quality and performance.

FAQs of B&W 8T 23 LH:

Q: How is the B&W 8T 23 LH lifting hook primarily used?

A: The B&W 8T 23 LH is mainly used for lifting and balancing marine engines and heavy equipment in shipyards and marine engineering environments. Its robust construction and manual operation enable safe and precise handling of loads up to 8 tons.Q: What benefits does the galvanized surface and IP54 rating provide?

A: The galvanized surface ensures superior resistance to rust and corrosion, while the IP54 rating protects the hook against dust ingress and moderate water exposure. These features make it suitable for harsh outdoor and marine conditions, extending its operational lifespan.Q: When should I choose the 8T 23 LH model for my application?

A: Choose the 8T 23 LH when you require a durable, high-capacity lifting hook designed specifically for manual, mechanical operation in marine or heavy equipment settings. Its 8-ton capacity and corrosion protection make it ideal for rigorous and repetitive lifting tasks.Q: Where can this lifting hook be installed?

A: The 8T 23 LH can be custom mounted for compatibility with various marine lifting cranes, gantries, and heavy equipment systems. Its standard dimensions and mounting adaptability allow easy integration into diverse lifting setups in shipyards and industrial sites.Q: What is the operating temperature range for this lifting hook?

A: This lifting hook can be used in environments ranging from -10C to 60C, making it versatile for use in different climatic conditions prevalent in marine and industrial applications.Q: How do I benefit from using an alloy steel, hand-operated lifting hook?

A: An alloy steel construction ensures strength and high durability, while manual operation allows precise control during lifting. This combination provides a reliable and efficient way to handle heavy marine engines safely and with reduced maintenance concerns.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in B & W Marine Engine Parts Category

Bergen KRG 6 Diesel Engine Spare Parts

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Usage & Applications : Suitable for Bergen KRG 6 Diesel Engines, used in marine, industrial, and power generation applications.

Weight (kg) : Varies by individual spare part component.

Operating Temperature : Designed for hightemperature engine operation environments.

Mounting Type : Directfit and OEMspecified mounting.

Marine Generator Spare Parts

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Usage & Applications : Marine generator maintenance and repair

Weight (kg) : Varies by part, typically 0.5 kg 25 kg

Operating Temperature : 20C to +120C

Mounting Type : Bolton or plugin depending on the part

B&W 26 MTBH-MTBF 40

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Usage & Applications : Industrial Applications, High Pressure Filtration, Mining, Oil & Gas, Power Plants

Weight (kg) : Approx 500 kg

Operating Temperature : 5C 55C

Mounting Type : Floor Mounted

B&W 320 MTBH 30

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units, ,

Usage & Applications : Industrial Water Treatment, Boiler Feed Water, Process Water, Cooling Towers, Power Plants

Weight (kg) : Approx. 150200 kg

Operating Temperature : 5C to 50C

Mounting Type : Floor Mounted

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry