ALCO 251

Price 1000.00 INR/ Unit

ALCO 251 Specification

- Working Pressure

- Up to 6 bar

- Operating Temperature

- Ambient to 150C (depending on process)

- Application Areas

- Pharmaceutical, laboratory, food & beverage, chemical industry

- Equipment Type

- Alcohol recovery/distillation system

- Flow Rate

- As per design specification

- IP Rating

- IP55 (if applicable for electrical cabinet)

- Capacity

- Custom

- Usage & Applications

- Alcohol and spirit recovery, distillation, and rectification in pharmaceutical, food & beverage, chemical, and allied industries.

- Product Type

- Distillation/Rectification Plant

- Type

- Alcohol Distillation Plant

- Material

- Stainless Steel (SS 304/316)

- Automatic Grade

- Automatic

- Control System

- PLC or Manual

- Drive Type

- Electric

- Weight (kg)

- As per design

- Dimension (L*W*H)

- Customized

- Feature

- High efficiency, robust construction, easy operation, energy saving, and low maintenance.

- Size

- Custom-built

- Voltage

- 220-415 V

- Surface Finishing

- Polished stainless steel

- Power Source

- Electric

- Features

- Corrosion resistant, compact design, energy efficient

- Mounting Type

- Skid mounted or floor mounted

ALCO 251 Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About ALCO 251

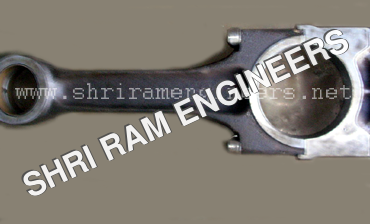

| ITEM NAME | PART NO. |

| PISTON RING SET | 24200413 |

| RING COMP PISTON (BARREL FACE) | 24210232 |

| RING COMP PISTON (TAPPER FACE) | 24210233 |

| RING SCRAPER PISTON | 24210210 |

| SHELL BEARING CON. ROD | 21710226 |

| SHELL BEARING CON. ROD CUP | 21710228 |

| LINER CYLINDER CHROME PLATED | 22110115 |

| GASKET LINER TO BLOCK UPPER | 2151452 |

| GASKET LINER TO BLOCK CENTER | 2151457 |

| VALVE AIR 30' | 22311211 |

| VALVE EXHAUST 40' | 2231129 |

| VALVE SEAT | 22211817-18 |

| SPRING AIR & EXHAUST VALVES | 2461082-1 |

| VALVE SEAT SPRING | 2231231 |

| GUIDE AIR & EXHAUST VALVE | 2231138 |

| PLUNGER & BARREL | 4321091 |

| NOZZLE 145', 400 MM | 22310226 |

| Material | Cast iron |

| Weight | 100kg |

Advanced Fractionating Technology

The ALCO 251 employs structured packing within its fractionating column to maximize contact area and separation efficiency. This modern design greatly enhances alcohol recovery and purity, making it ideal for critical distillation and rectification processes. The use of premium stainless steel also promotes long-term durability and corrosion resistance, ensuring consistent performance.

Flexible Operation and Process Control

The system offers both steam and electric heating options, with process control managed via a digital PLC and touch screen HMI, or manually if preferred. These features enable precise monitoring, easier operation, and quick adjustment of parameters to meet specific application needs in laboratories or large-scale plants.

Comprehensive Safety and Utility Integration

Safety is ensured by multiple devices including pressure relief valves, temperature cut-offs, and integrated alarm systems. The ALCO 251s design handles high temperatures and pressures safely, utilizing IP55 rated electrical cabinets and mineral wool insulation. It integrates seamlessly with utilities such as steam, cooling water, and electric supply for optimal performance.

FAQs of ALCO 251:

Q: How does the ALCO 251 achieve a high alcohol recovery rate?

A: The ALCO 251 utilizes a fractionating column with structured packing, which significantly increases surface area for vapor-liquid contact and improves separation efficiency. Combined with precise control over heat input and process conditions, this enables recovery rates of up to 98% depending on feed composition.Q: What safety features are incorporated in the ALCO 251 distillation plant?

A: This system is equipped with essential safety devices such as a pressure relief valve, a temperature cut-off mechanism, and an integrated alarm system to provide reliable protection during operation. These features ensure process safety and help prevent equipment or product loss.Q: Where can the ALCO 251 be installed and what are its main applications?

A: The ALCO 251 can be skid-mounted or floor-mounted, allowing installation flexibility in spaces ranging from laboratories to industrial production facilities. It is suitable for alcohol and spirit recovery, distillation, and rectification across pharmaceutical, food & beverage, laboratory, and chemical industries.Q: What process controls does the ALCO 251 offer for operation and monitoring?

A: Operators have the option of a digital PLC system with a touch screen HMI for real-time monitoring and process control, or manual operation if preferred. This flexibility allows for better adaptation to specific user requirements and enhances overall operational efficiency.Q: What are the primary utilities required to operate the ALCO 251?

A: The ALCO 251 requires steam or electrical heating, a cooling water supply for the condenser, and electrical power (220415 V, as per design). The system easily integrates with existing utility networks in industrial environments.Q: How does the robust construction benefit users of the ALCO 251?

A: Built with SS304/316 stainless steel and high temperature mineral wool insulation, the ALCO 251 offers excellent corrosion resistance, energy efficiency, and durability. Its rugged design ensures minimal maintenance and long service life, reducing downtime and operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Marine Engine Spare Parts Category

Emd Piston Ring

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Manual

Type : Others, Compression Ring, Oil Control Ring

Product Type : Piston Ring

Capacity : High performance under heavy load

COCKERILL L 8TR.240.C.O. ENGINE PARTS

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Manual

Type : Others, Diesel Engine Components

Product Type : Engine Parts

Capacity : 240 HP

Marine Engine Cylinder Liner

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Other, Manual Installation

Type : Others, Engine Part

Product Type : Cylinder Liner

Capacity : Customized as per engine requirements

Man 20/27 Engine Valve

Price 1000.00 INR / Unit

Minimum Order Quantity : 10 Units

Automatic Grade : Other, Manual operation

Type : Others, Intake Valve / Exhaust Valve

Product Type : Engine Valve

Capacity : High temperature and pressure endurance

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry